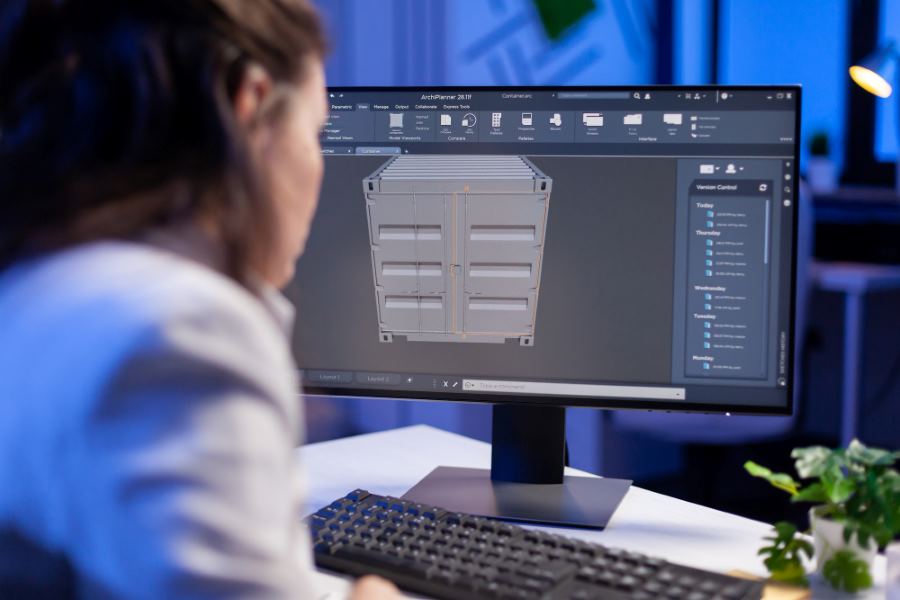

As we already know, the BIM methodology has a number of benefits in improving project efficiency, visualization, and centralizing information. One of the less mentioned aspects is that this working model also has a positive impact on inventory management and procurement logistics.

By having a complete BIM model, a team of professionals can project the necessary inputs for more precise material procurement, avoiding losses that reduce project efficiency. Likewise, this will allow us to easily track the flow of materials from acquisition to installation at the workplace and determine if there are leaks to take necessary measures at the site.

A useful example of a good practice in a BIM model is to include detailed information about material suppliers, delivery times, and storage locations on site. This allows the project team to plan ahead and efficiently coordinate material delivery to avoid construction delays.

Furthermore, BIM models help us optimize inventory management by accurately forecasting material needs. By analyzing the quantities and expected delivery dates in the model, project managers avoid over-purchasing materials, reduce costs associated with storage, and manage inventories more accurately.

Finally, the BIM methodology not only improves the accuracy of design and planning in the construction industry, but also optimizes inventory management and logistics, resulting in a more efficient and cost-effective supply chain for construction projects. Avoid errors in your models with Acero Estudio’s BIM consulting service, we are at your service.